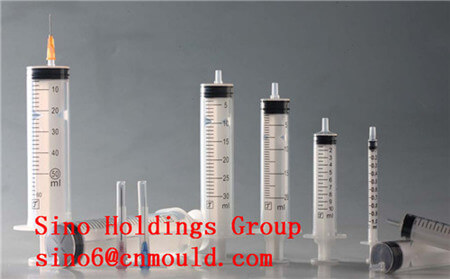

We supply disposable syringe mould, plastic injection molding machine and other auxiliary machinery. Casino holdings group supplies a complete set of equipment system for syringe production line. We have a Dakumar high-speed machine(www.dakumar.cn).We have provided more than 20 sets of equipment for different countries. The similar plastic mould and tube mould.

Cylinder piston mold

Cylinder size: 0.5 ~ 60 ml

Cylinder piston mold cavity number: 16 ~ 128 lumens

Cavity core steel material: use the Swedish Assab company Stavax S420, it is stainless steel and tempered steel material

Gate type: hot runner point gate (www.anole-hot-runner.cn) Arnold set injection system

Plastic products: PP or PE

Cylinder piston cavity core polishing: mirror polishing processing

Cylinder piston mold structure: the insert method is adopted, so that it set in the mold frame, mould the same in the parts are interchangeable.

Die life: at least 5 million die

Cylinder mould

The cavity number: 6 ~ 128 lumens

Cavity core steel material: use the Swedish Assab company Stavax S420, it is stainless steel and tempered steel material

Core slider: luer slider system

Injection gate type: hot runner point gate (www.anole-hot-runner.cn) Arnold set injection system

Plastic products: PP

Cylinder cavity core polishing, mirror polishing processing

Cylinder mould structure: the insert method is adopted, to make it set in the mold mold shelves, mold in the same parts are interchangeable.

Cylinder die life: at least 5 million die

Cylinder plug mold

Cylinder size: 1 ~ 50 ml

The mold cavity number can reach 160 cavity

Cavity core steel material: use the Swedish Assab company Stavax S420, it is stainless steel and tempered steel material

Slide block core: the luer slider system

Gate type: hot runner point gate (www.anole-hot-runner.cn) Arnold set injection system

Plastic products: TPE or medical PVC (such as the use of PVC, we do not recommend the use of thermal conductivity set)

Cavity core polishing, mirror polishing processing

Cylinder plug mold structure: the insert method is adopted, to make it set in the mold mold shelves, mold in the same parts are interchangeable.

Cylinder mill plug die life: at least 5 million.

Welcome to contact us, we can offer you disposable syringe turnkey project solutions.