Plastic chair is one of the daily uses nowadays. Why do people prefer using plastic chair? And do you know how to make the plastic chairs? Well, here we’d like to talk about the plastic chair production machines to help you learn the basics.

Reasons of Using Plastic Chair

Plastic chairs are:

- cheaper usually;

- lighter in weight;

- versatile;

- cleaned easily;

- recycled easily;

Expect the advantages of plastic chairs, one of key elements is that plastic chairs are allowed to be mass produced quickly.

Plastic Chair Production Machines

There are actually two types machines involved in manufacturing plastic chairs. To make it better to understand, show them by videos as follow.

1. Rotational Molding Machine for Plastic Chairs

2. Injection Molding Machine for Plastic Chairs

And there is special molding process with this type machine: gas-assisted injection molding, which is combined with necessary auxiliary equipment for gas pressuring to mould and mould designed for gas-assisted molding process.

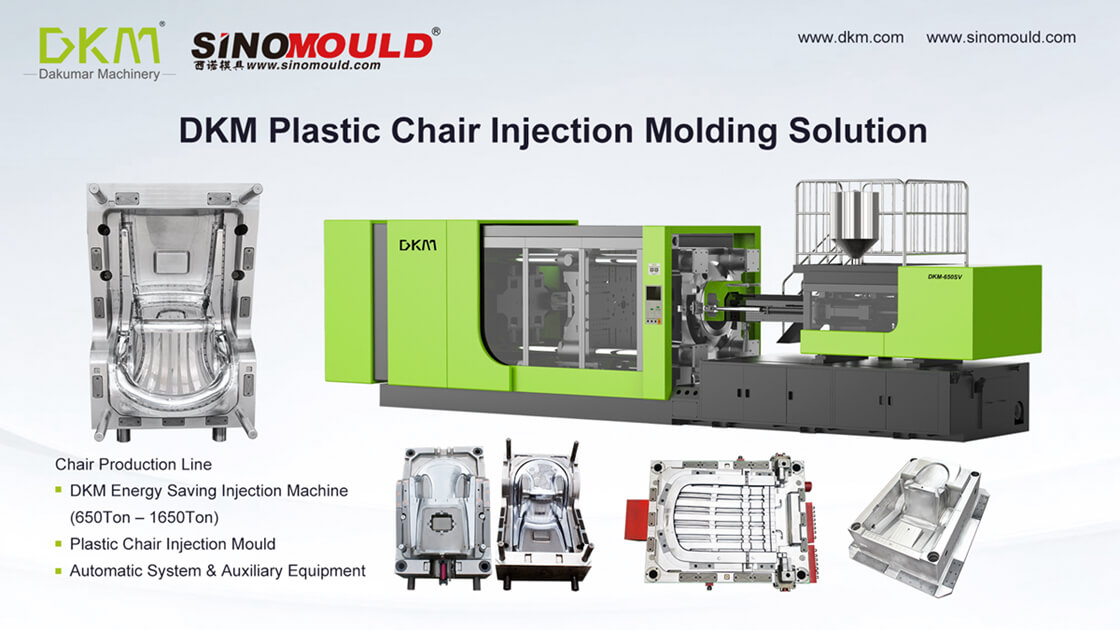

DKM Plastic Injection Molding Machine Recommend

The most popular models for chairs: DKM-650SV, DKM-850SV, DKM-1350SV, DKM-1650SV.

They could meet most of the requirements of popular plastic chairs production. And DKM engineers can provide the machines with function designed for you if any special demands.

Quick Access

Servo Motor Injection Moulding Machine

Popular Plastic Chairs

Popular Outdoor Resin Stack Chair

Outdoor Plastic Chairs

Plastic Folding Chair

Welcome to contact us for best plastic chair injection molding machines.