DKM-650 Victor Series: High-Speed Injection Molding Machine for Efficient 20L Paint Bucket

Plastic Painting Bucket Mould En la fabricación de envases de gran volumen, como cubos de pintura de 20 litros, la eficiencia, la precisión y el

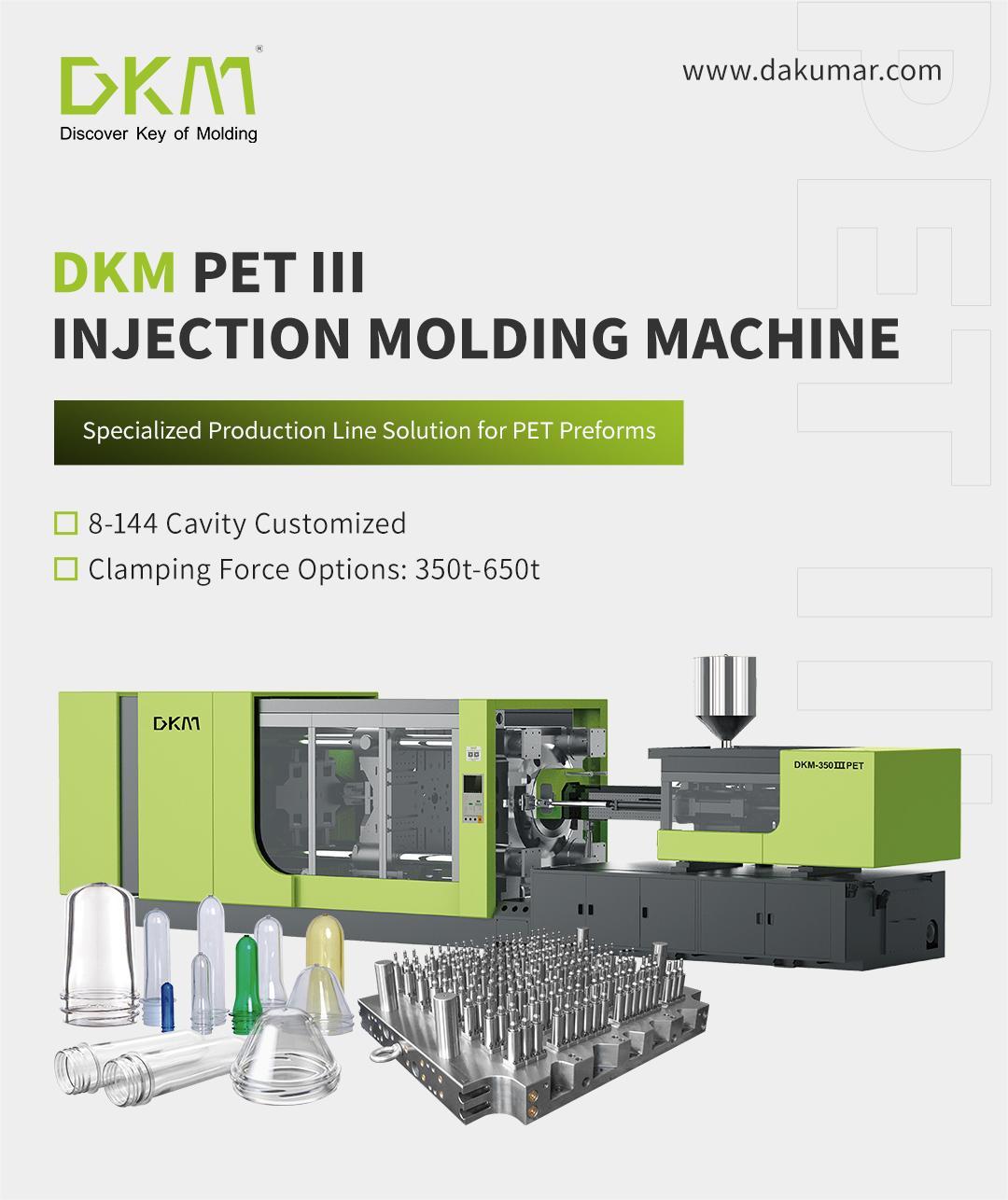

DKM se sitúa a la vanguardia de la tecnología de moldeo por inyección de preformas, ofreciendo soluciones de líneas de producción integradas reconocidas por su alta precisión, eficiencia excepcional y notable fiabilidad. Nuestra promesa central es entregar un sistema de alto rendimiento sin interrupciones —que abarca el molde de inyección de preformas, la máquina de inyección PET y el equipo auxiliar esencial— específicamente diseñado para producir preformas PET de alta calidad, con la ventaja distintiva de un período de entrega rápido de 2 semanas para preformas PET de cuello estándar de 48, 72 y 96 cavidades. Este artículo detalla las fortalezas clave que convierten a DKM en el socio óptimo para su éxito productivo.

Nuestros moldes son la base de la calidad, diseñados para una larga vida útil y una producción consistente.

Materiales y Construcción Superiores: Los moldes utilizan acero de alta calidad de la serie inoxidable para los componentes de conformado, garantizando alta dureza y una resistencia al desgaste excepcional.

Flujo y Enfriamiento Optimizados: El diseño de canales de enfriamiento unidireccionales en espiral asegura un intercambio de calor rápido y uniforme, reduciendo significativamente los tiempos de ciclo y estabilizando la calidad de la preforma.

Roscado de Precisión: El principio de posicionamiento de doble eje para la fabricación de roscas elimina defectos como rebabas, inconsistencias dimensionales y excentricidad.

Sistema de Canal Caliente Fiable: El sistema de canal caliente propio Anole, adaptado para moldes de preformas, permite el control individual de la temperatura de la cavidad, minimizando el riesgo de degradación térmica del plástico.

Nuestras máquinas PET proporcionan la potencia y el control necesarios para un moldeo preciso y eficiente.

Platos de Alta Rigidez: El análisis de elementos finitos (FEA) optimiza el diseño de los platos para una distribución uniforme de la tensión y una deformación mínima.

Diseño Especializado del Husillo: Un husillo dedicado ofrece excelente calidad de fusión, alta resistencia, resistencia a la corrosión y al desgaste, mejorando la capacidad de plastificación entre un 10-15% respecto a diseños tradicionales.

Seguridad y Eficiencia: Funciones como la protección del molde a baja presión, una función anti-arranque en frío del husillo y guías lineales garantizan una operación segura, alta precisión y bajo consumo energético.

Una línea de producción completa es más que las máquinas principales. DKM proporciona un conjunto completo de equipos auxiliares.

Cargador/Secador/Deshumidificador Tres en Uno: Para una preparación de material consistente.

Automatización Robótica con Enfriamiento Externo: Opciones de robots de enfriamiento externo de doble o triple estación para adaptarse a las demandas de su ciclo de producción.

Nuestro compromiso se extiende más allá del hardware hacia un apoyo total al proyecto.

Entrega Rápida en 2 Semanas: Para proyectos de preformas PET de cuello estándar, existen stocks de seguridad de material y piezas, y un proceso de producción estandarizado único. Ponga su línea en funcionamiento rápidamente, permitiendo un retorno de la inversión más acelerado.

Servicio Llave en Mano: Desde la planificación de la distribución en fábrica hasta un estricto control de calidad y pruebas previas al envío, proporcionamos una experiencia integral.

Soporte Técnico Directo: El departamento de I+D interno garantiza un servicio técnico rápido y experto, protegiendo la continuidad de su producción.

DKM es su socio estratégico para garantizar que su producción de preformas PET sea más inteligente y competitiva en el mercado.

Plastic Painting Bucket Mould En la fabricación de envases de gran volumen, como cubos de pintura de 20 litros, la eficiencia, la precisión y el

DKM es un fabricante profesional especializado en soluciones de moldes para contenedores clasificados de alta calidad, que ofrece una gama completa de modelos (32 L/45

In the fast-paced packaging industry, the ability to balance speed, customization, and reliability defines market competitiveness. The DKM PET Bottle Preform Production Line—equipped with high-precision injection

As a fast consuming demand increase for the thin wall containers, thin wall container production machine also become hot project. Many customers purchase the whole